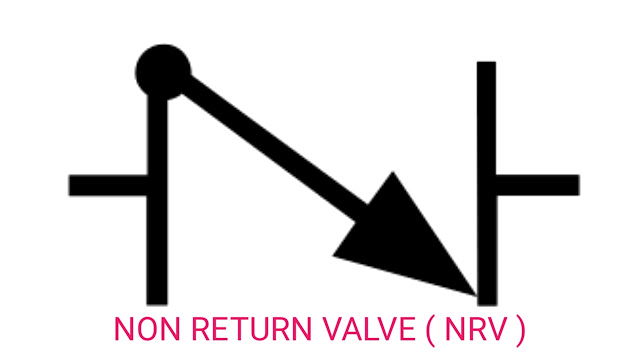

(NRV) Non Return Valve

A Non- Return Valves, check valve, clack valve, non- return valves, reflux valve, retention valve or one-way valve is a valve that normally allows fluid (liquid or gas) to flow through it in one direction only.

|

Non - Return valve/ Check valve are two-port valves, meaning that they have two openings in the body, one to enter the fluid and the other to release the liquid.

Types of (NRV) Non - Return Valves

There are various types of check valves/non-return valve used in a wide variety of applications. Non- return valves are often part of common household items.

Although they are available in a wide range of sizes and costs, Non - Return valve are generally very small, simple or inexpensive. Non - Return valve operate automatically and most are not controlled by an individual or any external control; Accordingly, most have no valve handle or stem. The bodies (outer shells) of most Non - Return valve/check valves are made of plastic or metal.

Importance Concepts in (NRV) Non - Return Valves

An important concept in the Non - Return valve/check valve is the cracking pressure which is the minimum differential upstream pressure between the inlet and outlet at which the valve will operate. Is usually designed for Non - Returnable valve/check valves and can therefore be specified for a specific cracking pressure.

Heart valve are essentially inlet and outlet check valves for the ventricles of the heart, as the ventricles act as pumps.

Thank you

Thanks for shared that blog with us. If anyone here searching swing check valve manufacturer in usa then visit Valves Only.

ReplyDeleteI wanted to thank you for this great Information and knowledge, I definitely loved every little bit of it. I have you bookmarked your web site to check out the latest stuff you post. Your blog is eye-catching. I get pleasure from it. Thanks for sharing this beautiful piece of writing with me, get more information at Top Entry ball valve manufacturer in USA for more Valves Only related information and knowledge.

ReplyDelete