CONSTRUCTION SITE PREPARATION:

Site Preparation:

Preparation of a Construction site is an important aspect which should focus on a good site layout access to the site and easy moment of vehicles in site.

Site Layout:

A badly planed and untidy construction site can lead to many accidents of construction site, which may arise from : (i) Fall of materials, (ii) Collision between the workers, (iii) plant or equipment. To avoid the above causes of accidents, a good layout of the side is a must while preparing the side layout atmost care should be taken to avoid overcrowding the site also enough space should be provided for the moment of man material and construction equipment with in the site.

Easy Access:

The construction sites should have easy and safe access. In this respect, the following parameters should be taken into consideration:

- Everyone should be able to get into the work site safely.

- Edges of scaffolding/ platform from where people could fall are provided with double guard rails or other suitable edges protection.

- Holes and pics are protected with clearly marketed and fix covers and barricades of prevent Falls.

- Site should be kept tidy and good housekeeping should be practiced.

- Provide good adequate lightning in all locations of the site.

- The site should be fenced off from the public.

Movement of Vehicles:

It is a common sight on the construction site that many vehicles ( trucks, cranes, fork lift, etc.) carrying construction materials move Criss - cross on the construction site, which result in a number of accidents and Mishaps. Construction site often operates on ground, which is muddy and uneven, and where driver visibility is poor. People walking on the site are injuries or killed by moving vehicles speciality reversing once. Many workers particularly drivers and operators are killed by all turning vehicles hence at most care should be taken for the moment of vehicles on the construction site the following points should be taken into consideration while moving the vehicles on the construction site.

- Vehicles and pedestrians should be kept apart on site, that is separate name as much as possible using barriers.

- Adequate clearance should be provided around vehicles.

- As far as possible avoid reversing the vehicles it is better to use one way system.

- Vehicles used on the sides must have reversing alarms/sirens.

Site Operations:

The type of operations/ activities carried out in the construction side are many and they vary from site to side. However, all of them should be carried out only with due regard to save operations. Some of the routine work/operations carried out in construction side are listed below:

- Evacuation work

- Scaffolding work

- Crane operations

- Hoisting Operations

- Forklift operations

- Ladder safety

- Electrical Safety

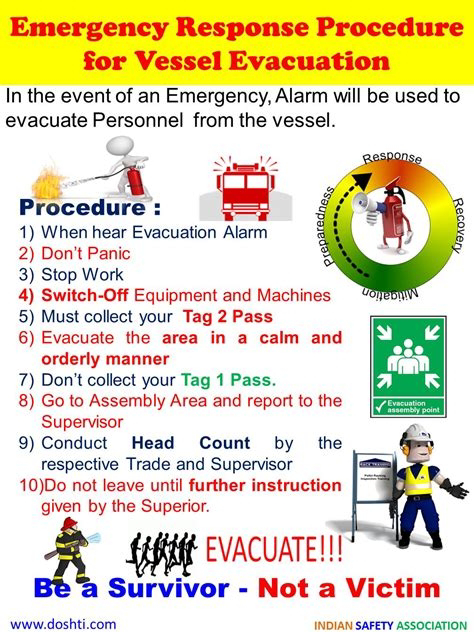

Evacuation Work:

Evacuation work is an important activity in the construction sites. However, many fatal accidents do occurs in evacuation work, ok if proper precautions are not taken.

Many lives are lost being Buried alive in the trenches. It should be remembered here that there is no save ground that will not collapse and therefore, any trench sides can collapse without any warning.

• All excavation work Deeper than 1.25 meters should be shored or battered.

• Evacuation Deeper than metres must be guarded by rails are barriers.

• Vehicles working, too close to the side of the trench or rubble piled on the side may cause collapse and therefore at most care should be taken.

• Vehicles tipping into the evacuation work must use stop blocks, so as so avoid the collapse of the trench.

• Make sure that the equation work is inspected daily.

• Make sure that you know where the position of underground pipes and electric cables are laid in the site so that you will not eat them during the evacuation work.

Scaffolding Work:

Scaffolds are temporary structures of Steel work, timber or bamboo. The criteria for their erection are the same as those for permanent structure. The strength of the scaffolding depends upon the combined strength of individual members. Failure of one or two of them can result in the collapse of the entire structure.

Modern scaffolders are invariably made of steel tubes, pre- fabricated in convenient unit.

They are safer and turn out good quality work. Of course, the Steel scaffolds are too costly, but it would be cheaper in the long run. In spite of the fact that the Steel scaffolds are much safer, many of the smaller and medium builders in India, neglect the safety aspect and prefer to use bamboo for timber falls in order to cut the cost. In any case, while erecting the scaffold, the workers should be force to wear necessary safety belts with fall arresters and helmets, so that the fall accident can be avoided.

Crane Operations:

Various type of grains are used in construction sites, which include (i) portable cranes, (ii) Tower cranes. A number of accidents are reported in the use of cranes, and many of them will be averted by adapting safe method of operations. Some of the methods are adopted for safe crane operators are given below:

• The weight of the load intended to be lifted by the crane must be careful estimated.

• The train must be lifted with an automatic safe load indicator.

• The train must always work on a hard level base.

• The load must be properly fix and secured.

• The single man must be trained to give clear signals.

• The ropes, hooks, chains, slings, etc. used in the lifting operations must be inspected regularly for their worn out.

• When mobile trains are used, care must be taken to prevent overturning of crane.

• Wear appropriate personal protective equipment.

Forklifts Operations:

The fork lift are very commonly used in construction sites for moment of Many construction materials and stacking them at heights. The shows a line diagram of a fork lift with various parts. While operating the fork lifts, the following general safety guidelines should be observed:

• Ensure that the forklift has an overhead barriers to protect the operators from falling.

• Do not allow Riders on the fork lift.

• Do not raise peoples on the fork lift.

• Always work within the capacity limits of your fork lifts.

• Before modifying the operations or capacity limits of the forklift, consult with the manufacturer.

• Do not operate a Forklift in an area with hazardous concentrations of acetylene, butadiene, hydrogen, ethylene or diethyl ether, or other explosive environment.

• Never lift a load while moving a forklift. Wait until you are complete list of paid before facing the mast.

• Be sure the top load sits squarely on the stocks. Remember uneven load could topple the Forklift.

• When you want to travel with load slightly lift the load back to provide stability.

• Make sure that you travel with loads at the proper height. A stable clearance height is usually for 4 to 6 inches at the tips and 2 inches at the Heels of the fork blades.

• When preparing to level of the forklifts unattended, lower mast, neutralize the controls, shut the power off, and set the brakes.

• If you cannot see over the lord drive in reverse do not try to look around a lots and drive forward.

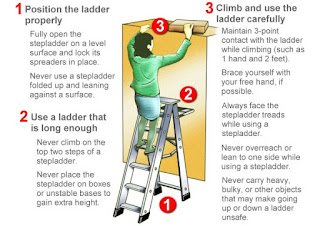

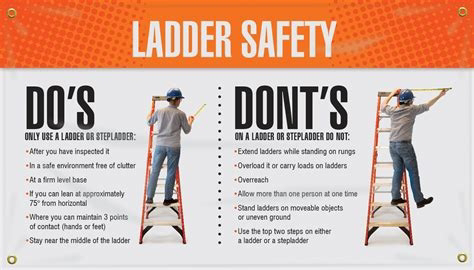

Ladder Safety:

Ladder are one of the most popular items used in the construction sites for working at heights. However, if not used safely, it can kill a lot of people. The depict the wrong and right way of using the ladders. The following safe methods should be adopted while operating ladders:

• Always have a firm grip on the ladders and keep a good balance.

• Never allow more than one person on a ladder.

• Use tools belts or hand line to carry objects when you are climbing the ladder.

• If you have a fear of heights - do not climb a ladder.

• Do not allow to work under a ladder in use.

• Do not use defective ladder.

Conclusion:

The construction is the largest economic activity in the India after agriculture. It contribute more than 5% of India's GDP and about 78% of the gross capital formation. The construction sector is the most vulnerable segments of the unorganised labour in India. About 165% 1000 workers get injured in the construction site. The rate of fatal accidents in construction sector is 4 to 5 times that of the manufacturing sectors. "Falls" account of highest causes of death which is about 3.2 % of the total accidental death reported in India for the year 2013.

The largest number of workers are exposed to the risk of workplace accident and occupational health problems in the construction site. Althoughts there are a number of Indian regulations dealing with the working conditions of construction workers their effectiveness are yet to be felt. No doubt that a worker who becomes a ill or injured as a result of unlawful negligence can use for compensation, which could turn into a significant amount, if it is true as a serious injury or illness.

It is a fact that in spite of all the efforts taken by some of the elite construction companies and safety enforcement authorities, accidental and illness in the Constructions site and still on the rise and lack of awareness was evident in many cases. Hence, more attention should be paid to arouse the safety awareness of construction workers. Above all, everyone who is involved in the construction activities should shoulder the responsibility of identifying the potential hazards and make all effects to eliminate them from the construction sites. Thus the "mantra" is that every job on the construction site must be carried out with at-most safety.

Comments

Post a Comment