HOUSEKEEPING SAFETY

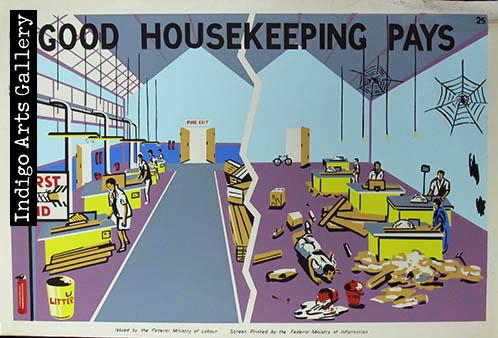

Effective housekeeping can eliminate some workplace hazards and health get a job done safely and properly. Poor housekeeping can frequently contribute to accidents by hiding hazardous that causes injuries. If the sight of paper, debris, clutter and spills is accepted as normal, then other more serious health and safety hazards may be taken for granted.What is Housekeeping?

Housekeeping is not just cleanliness. It include keeping work areas neat and orderly; maintaining halls and floors free e of slip and trip hazards; and removing of waste materials (e.g. papers cardboards) and other fire hazards from work areas. It also requires paying attention to import details such as the layout of the whole work place, aisle marking, the adequacy e of storage facilities, and maintenance. Good housekeeping is also a basic part of accident and fire prevention.

Effective housekeeping is an ongoing operation: it is not a hit and miss clean up done occasionally. Periodic "panic" clean abs are costly and ineffective in reducing accidents.

Purpose of Workplace Housekeeping:

Poor housekeeping can be causes of accidents such as

- Tripping over losers objects on floors, stairs and platforms.

- Being hit by falling objects

- Sleeping on greasy, wet for dirty surface

- Striking against projecting, poorly stacked items for misplaced material

- Cutting, puncturing or tearing the skin of hands or other parts of the body on projecting nails wire or steel strapping.

To avoid these hazards, the workplace must "maintain" order throughout a workday. Although this efforts requires a great deal of management and planning the benefits are many.

Benefits of Good Housekeeping:

Effective housekeeping results in:

- Reduce handling to ease the flow of materials.

- Fower tripping and sleeping accidents in flutter free and spill free work areas

- Decrease fire hazards

- Lower worker exposures two hazardous substance ( e.g. Dust, vapors )

- Better control of tools and materials, including inventory and supplies

- More efficient equipment clean up and maintenance

- Better hygienic conditions leading to improve health

- More effective use of space

- Reduced property damage by improving preventive maintenance

- Less janitorial work

- Improve moral

- Improve productivity ( tools and materials will be easy to find ).

Subscribe EngineeriSafety To Get Notifications of Posts

Comments

Post a Comment